43) Get wired!

This mess of wires is what I pulled from the donor Legacy. I know it's not necessary to get every wire from the Suby, but I wanted to be sure I could trace every wire needed. For example the tach and speedometer wires end up in the dash harness, and go to the speedo cluster.

This is after extracting each wire from the ECU. I unwrapped all the black corrugated piping and electrical tape. What a sticky mess that was!

Here's the Suby firewall grommet that I'm reusing. I fed each wire through it while I was shortening each ECU wire -> sensor or plug. I soldered each wire, and used a glue type shrink wrap to seal it all up.

Here I'm measuring the length of each connection. I wanted to get the lengths roughed in before I solder everything in and reapply all the wire protection.

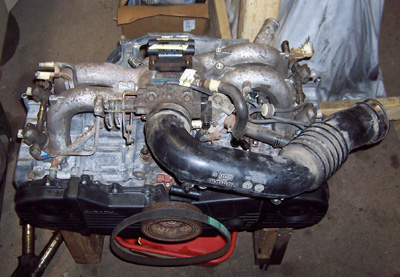

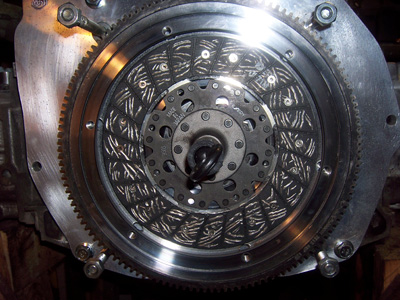

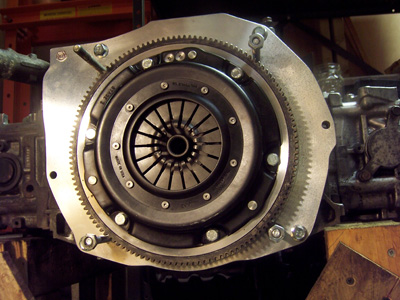

Labels: engine