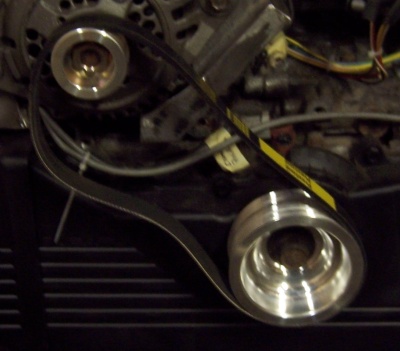

42) Alternator belt

With the new alternator bracket in place, I now had a bit of an issue with finding the right belt that would fit. This belt was too tight, and wouldn't fit with the alternator adjusted as low as it could go. The next belt size up was too long and the alternator didn't have enough adjustment to make it tight.

I then decided to get a set of smaller pulleys to see if my smallest belt would fit.

No luck, the smallest belt now is too big for these small pulleys.

I finally found a belt that was the perfect length, and allowed me to tighten it right about midway through the adjustment of the alternator! The only possible problem here is that this belt has skinnier then the OEM belt. I'm guessing that since this is only driving the alternator that it should hold up fine :) *Fingers Crossed*